Premium Precision

A new approach to metal fabrication

Experience unparalleled precision and performance we are your ultimate partner. From prototype to production, we deliver exceptional parts, services, and value.

One call. One partner. Excellence engineered for your success.

One Stop for all

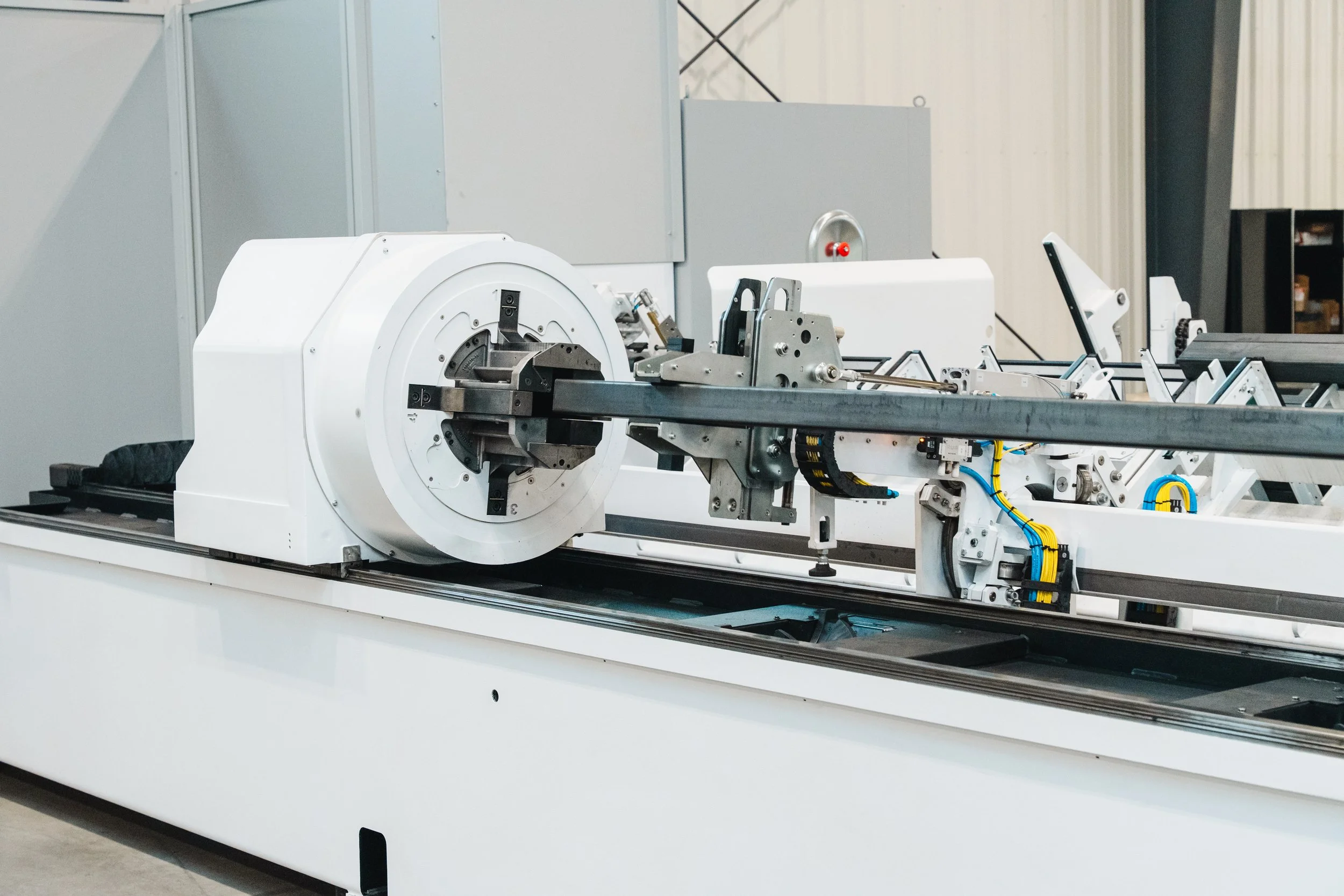

Tube laser

The finest products are crafted with precision-engineered tubing. At Bemidji Steel Company, our expert team leverages cutting-edge technology and deep industry knowledge to optimize every part and tube for maximum performance and durability. We don’t just supply materials — we innovate solutions that enhance your product’s quality while reducing costs. Partner with us to unlock the full potential of tube-based designs, ensuring your products stand out in excellence and efficiency. Transform your manufacturing process with tubing engineered for success.

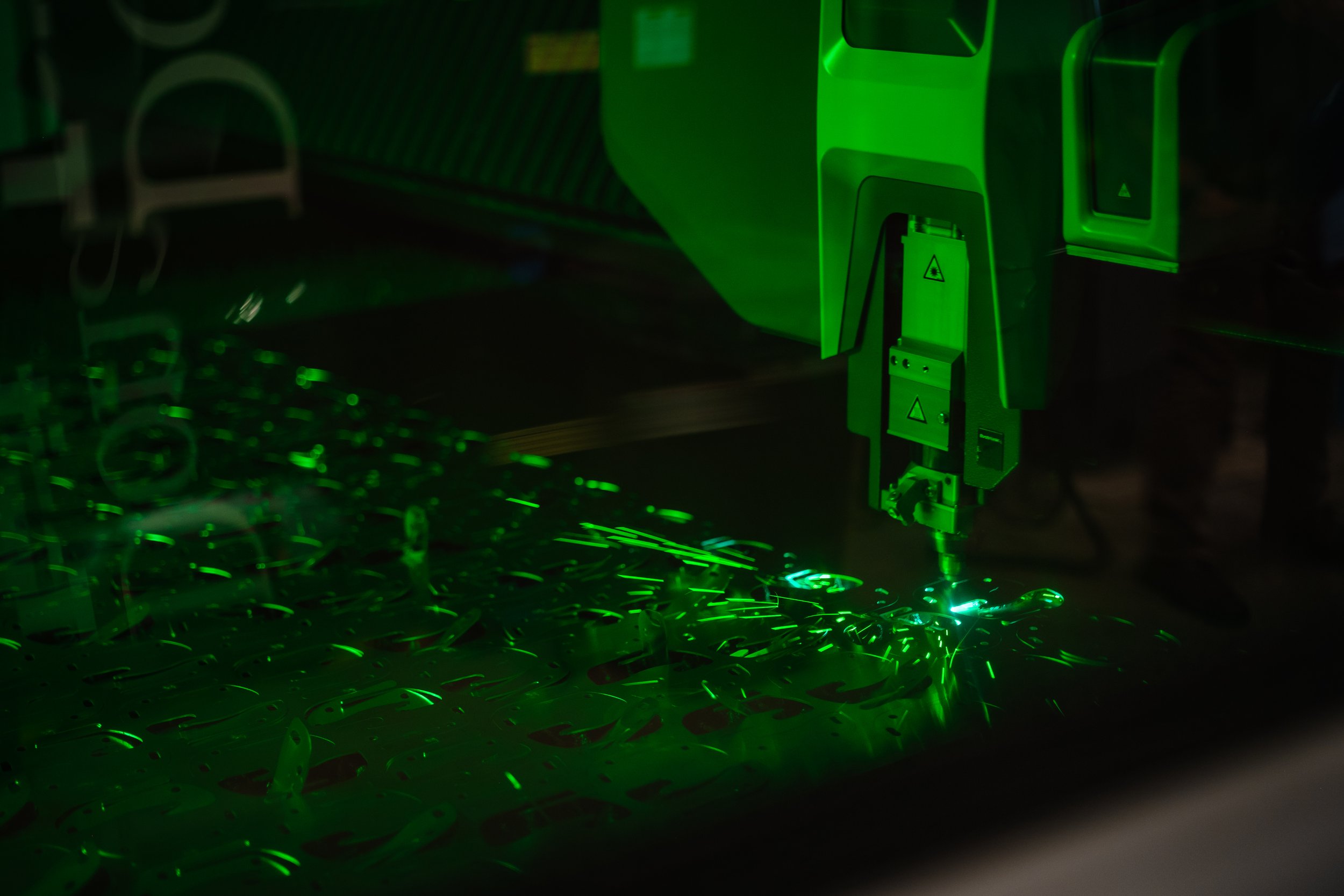

Flat laser

The ultimate parts originate from the most advanced lasers in the world. Unmatched technology seamlessly integrates high speed and unparalleled precision, delivering parts that exceed expectations. Every cut, every detail, crafted to perfection, ensures you receive parts of the highest quality—engineered to enhance performance, durability, and excellence. This is not just laser manufacturing; this is the ultimate standard in parts production.

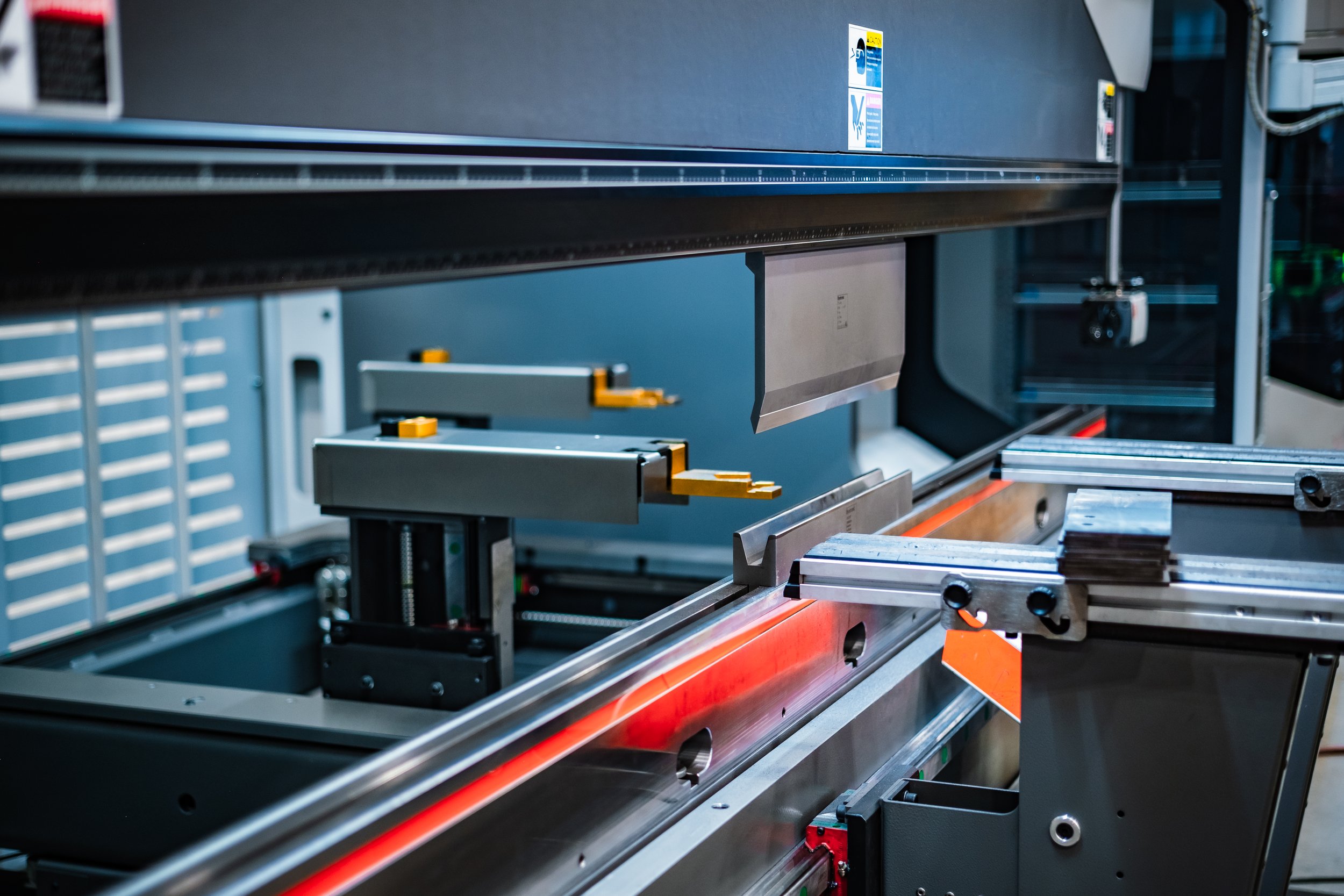

Forming

Functional performance begins with flawless forming. We integrate cutting-edge precision machinery with specialized expertise to guarantee parts that meet your exact specifications from the outset. Leveraging advanced digital modeling, our automated systems and skilled technicians collaborate seamlessly to produce consistently accurate bends and shapes. This fusion of technology and craftsmanship ensures that every component delivers optimal functionality and reliability, aligning perfectly with your rigorous standards.

Make it Perfect

The ultimate parts are finished to perfection. From precision edge finishing to flawless paint application, Bemidji Steel Company sets the standard for excellence. Every component reflects unmatched craftsmanship, engineered with meticulous attention to detail. This is not just manufacturing—it’s a commitment to creating exceptional parts that define performance and quality. Bemidji Steel Company: where perfection is standard, and excellence is expected.

Expert assistance to elevate your parts